PRODUCTS

PET Short Fiber Nonwoven Geotextile

Email : taiwei@cngeosynthetics.com

Category:

PET Short Fiber Nonwoven Geotextile

keywords :

PET Short Fiber Nonwoven Geotextile

Product Introduction

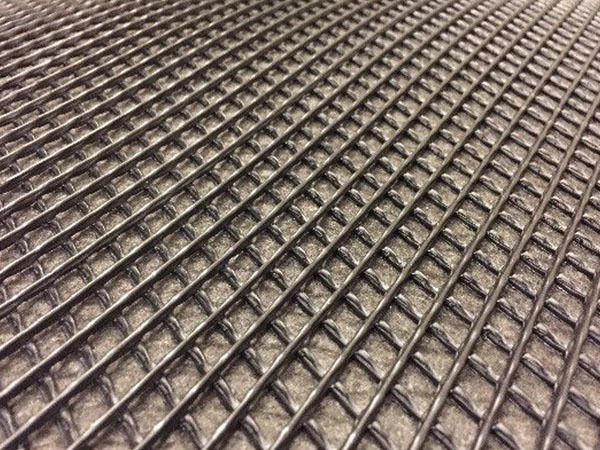

Polyester short fiber non-woven geotextile is a non-woven geotextile material made from polyester (PET) short fiber through opening, carding, netting and needle punching processes. This product combines the functions of isolation, filtration, drainage and protection. It is widely used in highways, water conservancy, environmental protection, agriculture and other fields.

Product specifications

Weight: 100-800g/㎡ (customizable according to customer needs)

Size: Width 1-6m/Length (customizable according to customer needs)

Color: white, black, green, etc. (customizable according to customer needs)

Packaging: normal neutral packaging (customizable according to customer needs)

| Index Properties | Test Method | Unit | |||||||||||||

| Weight | ASTM D5261 | g/m2 | 100 | 125 | 150 | 200 | 250 | 300 | 350 | 400 | 450 | 500 | 550 | 600 | |

| Ultimate Tensile Strength | ASTM D4595 | ≥kN/m | 2.5 | 3.5 | 4.5 | 6.5 | 8 | 9.5 | 11 | 12.5 | 14 | 16 | 17.5 | 19 | |

| Tensile Elongation | ASTM D4595 | % | 50 | ||||||||||||

| Grab Tensile Strength | ASTM D4632 | ≥N | 225 | 280 | 361 | 641 | 720 | 792 | 911 | 1036 | 1182 | 1346 | 1480 | 1584 | |

| Grab Elongation | ASTM D4632 | % | 50 | ||||||||||||

| Trapezoid Tear Strength | ASTM D4533 | ≥N | 80 | 100 | 120 | 160 | 200 | 240 | 280 | 330 | 380 | 420 | 440 | 460 | |

| CBR Puncture Strength | ASTM D6241 | ≥kN | 0.3 | 0.4 | 0.6 | 0.9 | 1.2 | 1.5 | 1.8 | 2.1 | 2.4 | 2.7 | 2.9 | 3.2 | |

| Puncture Resistance | ASTM D4833 | ≥N | 82 | 99 | 133 | 225 | 284 | 346 | 440 | 530 | 596 | 603 | 663 | 760 | |

| Drop Cone Resistance(hole-φ) | BS EN 918 | mm | 45 | 40 | 37 | 34 | 31 | 26 | 23 | 19 | 18 | 16 | 15 | 15 | |

| Hydraulic Properties | |||||||||||||||

| Apparent Opening Size O90 | ASTM D4751 | ≤mm | 0.13 | 0.12 | 0.12 | 0.12 | 0.12 | 0.11 | 0.1 | 0.09 | 0.08 | 0.08 | 0.08 | 0.08 | |

| Permeability | ASTM D4491 | cm/s | 0.41 | 0.41 | 0.41 | 0.41 | 0.4 | 0.4 | 0.39 | 0.39 | 0.39 | 0.39 | 0.39 | 0.39 | |

| Physical Identification Properties | |||||||||||||||

| Thickness | ASTM D5199 | mm | 1 | 1.3 | 1.7 | 2.1 | 2.4 | 2.5 | 2.8 | 3 | 3.2 | 3.5 | 3.6 | 3.8 | |

| Roll Width | – | m | 1-6 | ||||||||||||

Application

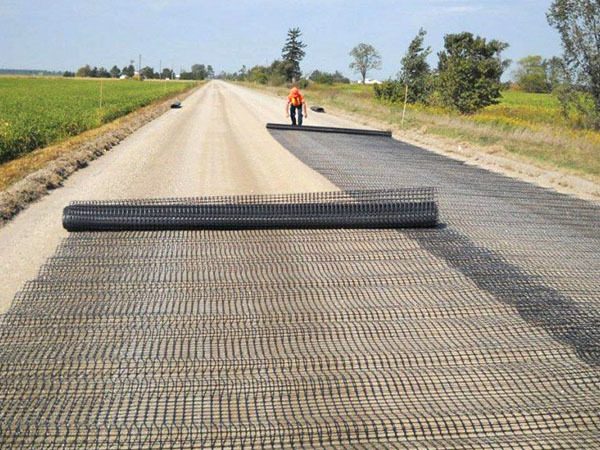

1. Highway and railway engineering

Subgrade isolation: Prevent soft soil from mixing with fill and reduce subgrade settlement.

Drainage system: laid on the back of the roadbed or retaining wall to discharge seepage water.

2. Water conservation and flood control projects

Channel anti-filtration layer: protects the dam soil from being washed away by water flow.

Temporary flood control sandbag lining: enhance the soil retention and durability of the sandbags.

3. Environmental protection projects

Landfill covering layer: covering the garbage pile to prevent dust and seepage.

Constructed wetland base layer: Provides a stable water permeable structure to assist water purification.

4. Agriculture and Gardening

Suppresses the growth of weeds and reduces the use of pesticides; it is water and breathable and protects the soil structure.

5. Temporary engineering and disaster emergency

Construction site dust and rain erosion prevention to reduce soil erosion.

Features

1.High temperature resistance

Polyester material has a higher melting point and good high temperature resistance

2. Uniform water permeability and filtration performance

The fibers are randomly distributed to form uniform pores with good water permeability, which can effectively intercept fine-grained soil and prevent siltation. It has horizontal water conduction ability and is suitable for drainage layer or anti-filtration layer.

3. Isolation and protection

Prevent different materials (such as soil and gravel) from mixing with each other and maintain structural layering stability.

As a protective layer, it covers the surface of the geomembrane to avoid mechanical damage or direct ultraviolet rays.

4. Environmental protection and durability

Acid, alkali and mildew resistant. Recyclable, in line with the concept of green construction.

5. Convenient construction

Soft texture, good fit, easy to lay on complex terrain; can be cut, sewed or overlapped, high construction efficiency.

Packaging and shipping

We are willing to package and ship products according to the weight, specifications, materials, economic costs and customer requirements.

Customer review

Customer visits

Exhibition

Certification

Our products are applied in these fields

Non woven geotextile

Geonet

LLDPE Geomembrane

HDPE Geomembrane

Uniaxial Geogridac

Triaxial Geogrid

Steel-Plastic Geogrid

PP Biaxial Geogrid

PET Geogrid

Fiberglass Geogrid

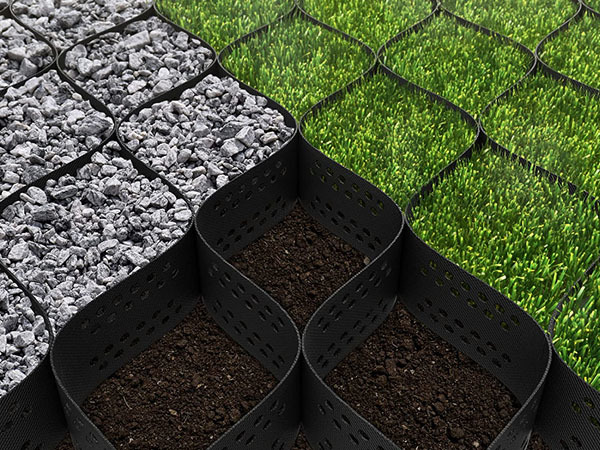

Geocell

Non woven geobag

Frequently Asked Questions

— What is your method of payment?

We accept T/T, L/C, Western Union or negotiation. Don't worry about anything, if you have any questions please feel free to contact us.

— How long is your delivery time?

Small orders take about one week, large orders need to be negotiated based on factory orders.

— How do you guarantee the quality of the product for us?

We have a professional quality control team, and each product is strictly inspected before shipment.

— Can you have our brand printed on your products?

Yes. If you can meet our MOQ, we can print your logo on the product and packaging.

— Can we get the sample from your factory?

We can provide you with samples for free, but you need to pay the express fee before the first cooperation.

— Do you accept processing orders?

We provide OEM and ODM services to customers.

GET A FREE QUOTE

RELATED PRODUCTS