PRODUCTS

UV-resistant PET filament non-woven geotextile

Email : taiwei@cngeosynthetics.com

Category:

PET Filament Nonwoven Geotextile

keywords :

PET Filament Nonwoven Geotextile

Product Introduction

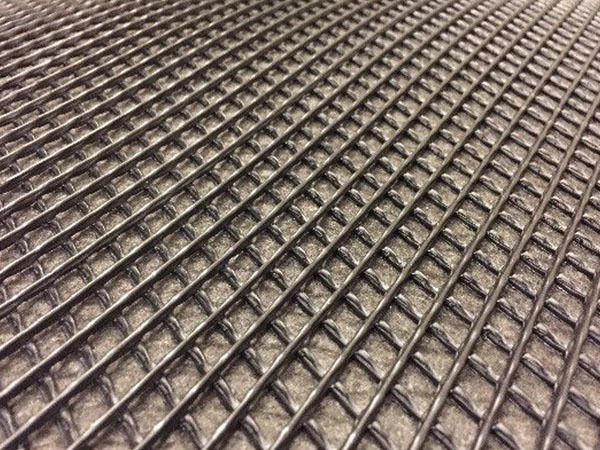

PET filament nonwoven geotextile is an advanced technical textile manufactured from 100% polyester (PET) polymer through a continuous spunbond process. Characterized by its interlocking network of continuous filament fibers, the material offers excellent mechanical properties, high tensile strength, and a UV-stabilized structure that maintains the geotextile's performance. This makes it an ideal solution for critical infrastructure applications such as railway bed stabilization, landfill liner protection, coastal erosion control systems and sustainable drainage solutions.

Product specifications

Weight: 100-1000g/㎡ (customizable according to customer needs)

Size: Width 1-7m/Length (customizable according to customer needs)

Color: white, black, green, etc. (customizable according to customer needs)

Packaging: normal neutral packaging (customizable according to customer needs)

| Index Properties | Test Method | Unit | Values | |||||||||

| TW100 | TW150 | TW200 | TW250 | TW300 | TW350 | TW400 | TW450 | TW500 | TW600 | |||

| Color | – | White or Black | ||||||||||

| Ultimate Tensile Strength, MD/TD | ASTM D4595 | kN/m | 7 | 9.5 | 13 | 17 | 19 | 22 | 25 | 29 | 34 | 38 |

| Tensile Elongation | ASTM D4595 | % | 45 | 45 | 50 | 50 | 50 | 60 | 60 | 60 | 60 | 60 |

| Grab Tensile Strength, MD/TD | ASTM D4632 | N | 450 | 550 | 730 | 1000 | 1250 | 1400 | 1700 | 1850 | 2000 | 2500 |

| Grab Elongation | ASTM D4632 | % | 45 | 45 | 50 | 50 | 50 | 60 | 60 | 60 | 60 | 60 |

| Trapezoid Tear Strength, MD/TD | ASTM D4533 | N | 180 | 270 | 330 | 430 | 450 | 540 | 610 | 700 | 770 | 900 |

| CBR Puncture Strength | ASTM D6241 | N | 1100 | 1800 | 2300 | 2700 | 3200 | 3600 | 4400 | 4800 | 5800 | 6900 |

| Apparent Opening Size O90 | ASTM D4751 | mm | 0.11 | 0.11 | 0.11 | 0.1 | 0.09 | 0.09 | 0.08 | 0.08 | 0.08 | 0.08 |

| Water Flow Q100 | ASTM D4491 | L/m2/s | 235 | 235 | 220 | 200 | 185 | 165 | 125 | 110 | 90 | 80 |

| U.V. Resistance | ASTM D4355 | % @ 500h | 70 | 70 | 70 | 70 | 70 | 70 | 70 | 70 | 70 | 70 |

| Weight | ASTM D5261 | g/m2 | 100 | 150 | 200 | 250 | 300 | 350 | 400 | 450 | 500 | 600 |

| Thickness | ASTM D5199 | mm | 0.8 | 1.2 | 1.6 | 1.9 | 2.2 | 2.5 | 2.8 | 3.2 | 3.4 | 4.5 |

| Roll Width | – | m | 1-7 | |||||||||

| Roll Length | – | m | 50-200 | |||||||||

Application

1. Water conservancy initiatives: Measures for preventing seepage, landslide mitigation, and erosion control in rivers, dams, reservoirs, and other water conservancy initiatives.

2. Foundation initiatives: Techniques for soil reinforcement, seepage prevention, and soil conservation aimed at enhancing the stability and dependability of foundation initiatives.

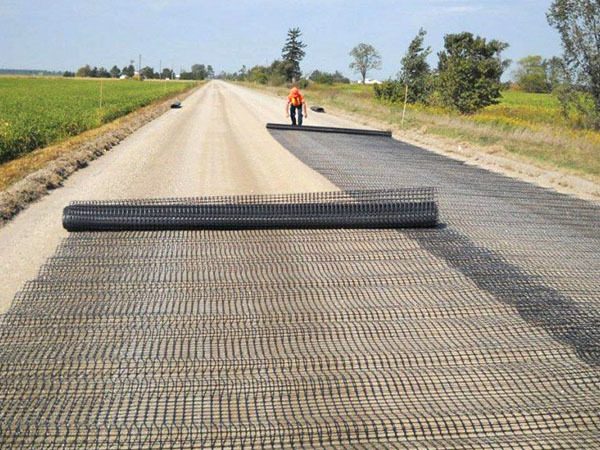

3. Road initiatives: Methods for reinforcing and stabilizing roadbeds to minimize the likelihood of road cracks and subsidence, thereby prolonging the lifespan of roads.

4. Mining and landfill management: Holistic oversight of mining operations, along with reinforcement and seepage prevention in landfills to mitigate soil and groundwater contamination.

5. Agricultural initiatives: Strategies for wind protection and thermal insulation, moisture retention in soil, and overall soil management to foster crop development and boost yields.

Features:

1. Exceptional strength and durability

Made from continuous polyester filament, it exhibits high tensile strength, minimal elongation, and slight deformation under prolonged load. It is resistant to acids and alkalis, as well as UV aging.

2. Superior permeability and filtration capabilities

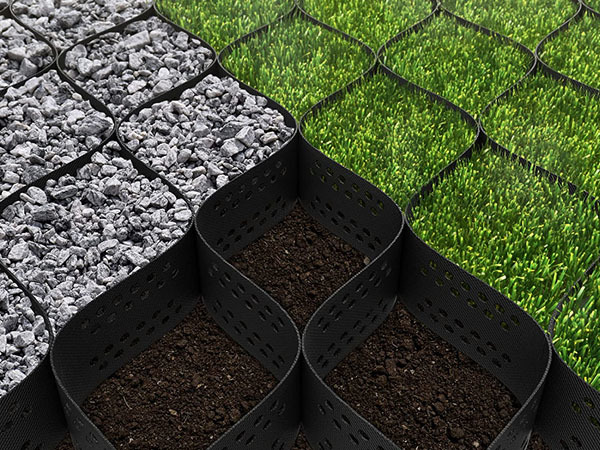

The three-dimensional pore structure guarantees effective water permeability while efficiently capturing soil particles during drainage.

3. Isolation and reinforcement

Prevent mixing between different soil layers or fillers and maintain structural stability. After combining with the soil, it disperses stress, improves the capacity bearing of the foundation, and reduces settlement.

4. Environmental protection and adaptability

The raw materials are recyclable, the production process consumes low energy, and meets green engineering standards.

5. Convenient construction

The roll is light and has high laying efficiency. It can be cut on site, and the overlap is stitched or thermally bonded to save construction time.

Product qualification

1.Product quality certification: Passed ISO9001 quality management system certification, CE certification, etc.

2.Product test report: Provide product test reports issued by authoritative organizations.

Packaging and shipping

We are willing to package and ship products according to the weight, specifications, materials, economic costs and customer requirements.

TW® Nonwoven Geotextile is a permeable geosynthetic material composed of synthetic fibers, including polyester (PET) and polypropylene (PP), produced through advanced techniques like needle punching or spunbonding. Its fabric-like texture offers outstanding filtration, separation, drainage, reinforcement, and protection, in addition to cushioning and anti-seepage features. This product serves as a crucial foundational element in contemporary civil engineering, hydraulic engineering, and environmental engineering.

Customer review

Customer visits

Exhibition

Certification

Our products are applied in these fields

Non woven geotextile

Geonet

LLDPE Geomembrane

HDPE Geomembrane

Uniaxial Geogridac

Triaxial Geogrid

Steel-Plastic Geogrid

PP Biaxial Geogrid

PET Geogrid

Fiberglass Geogrid

Geocell

Non woven geobag

Frequently Asked Questions

— What is your method of payment?

We accept T/T, L/C, Western Union or negotiation. Don't worry about anything, if you have any questions please feel free to contact us.

— How long is your delivery time?

Small orders take about one week, large orders need to be negotiated based on factory orders.

— How do you guarantee the quality of the product for us?

We have a professional quality control team, and each product is strictly inspected before shipment.

— Can you have our brand printed on your products?

Yes. If you can meet our MOQ, we can print your logo on the product and packaging.

— Can we get the sample from your factory?

We can provide you with samples for free, but you need to pay the express fee before the first cooperation.

— Do you accept processing orders?

We provide OEM and ODM services to customers.

GET A FREE QUOTE

RELATED PRODUCTS