PRODUCTS

HDPE Geomembrane

Email : taiwei@cngeosynthetics.com

Category:

Geomembrane

keywords :

Geomembrane

Product Introduction

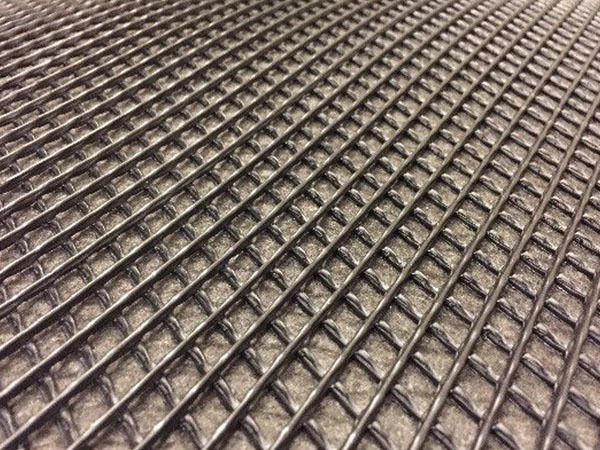

HDPE geomembrane is produced using a three-layer blow molding process or a calendering process and is an effective waterproof barrier engineering material.

1. Excellent anti-penetration performance, waterproof, anti-seepage and isolation

2. Good chemical corrosion resistance

3. Has good impact resistance and wear resistance

Product specifications

Thickness: 0.2-3mm (customizable according to customer needs)

Size: Width 1-10m/Length (customizable according to customer needs)

Color: black,white green, etc. (customizable according to customer needs)

Packaging: normal neutral packaging (customizable according to customer needs)

Technical indicators

| Test Unit Standard Test Frequency | |||||||||||||||

| Mechanical Properties | Thickness | mm | ASTMD5199 | 0.2 | 0.3 | 0.4 | 0.5 | 0.75 | 1 | 1.25 | 1.5 | 2 | 2.5 | 3 | Per roll |

| Density | g/cc | ASTMD1505/D792 | 0.94 | 90,000 kg | |||||||||||

| Asperity Height | ASTM D7466 | 0.25mm | |||||||||||||

| Tensile Properties | kN/m kN/m | ASTMD 6693 | 3 | 5 | 6 | 7 | 11 | 15 | 18 | 22 | 29 | 37 | 44 | 9,000 kg | |

| · yield strength | % | Type IV | 5 | 8 | 11 | 13 | 20 | 27 | 33 | 40 | 53 | 67 | 80 | ||

| · break strength | % | 12 | 12 | 12 | 12 | 12 | 12 | 12 | 12 | 12 | 12 | 12 | |||

| · yield elongation | 700 | 700 | 700 | 700 | 700 | 700 | 700 | 700 | 700 | 700 | 700 | ||||

| · break elongation | |||||||||||||||

| Tear Resistance | N | ASTM D 1004 | 25 | 38 | 50 | 62 | 93 | 125 | 156 | 187 | 249 | 311 | 374 | 20,000 kg | |

| Puncture Resistance | N | ASTM D 4833 | 64 | 96 | 128 | 160 | 240 | 320 | 400 | 480 | 640 | 800 | 960 | 20,000 kg | |

| Stress Crack Resistance | hr. | ASTM D 5397 | 500 hr. | per GRI GM-10 | |||||||||||

| Carbon Black Content | % | ASTM D 4218 | 2.0-3.0% | 9,000 kg | |||||||||||

| Carbon Black Dispersion | ASTM D 5596 | For 10 different views: 9 in Categories 1 or 2 and 1 in Category 3 | 20,000 kg | ||||||||||||

| Reference Properties | Oxidative Induction Time | min | ASTM D 3895 | 100 min. | 90,000 kg | ||||||||||

| (a) Standard OIT | ASTM D 5885 | 500 min. | |||||||||||||

| (b) High Pressure OIT | |||||||||||||||

| Oven Aging at 85°C retained after 90 days | % | ASTM D 5721 | 55% | per each formulation | |||||||||||

| (a) Standard OIT - % | ASTM D 3895 | 80% | |||||||||||||

| (b) High Pressure OIT - % | ASTM D 5885 | ||||||||||||||

| UV Resistance | % | ASTM D 5885 | 50% | per each | |||||||||||

| High Pressure OIT - % retained | formulation | ||||||||||||||

| Melt Index,condition 190°C/2.16kg | ASTM D1238 | 0.20g/10min | |||||||||||||

| Roll size | Dimensional Stability | % | ±2 | ||||||||||||

| width | m | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | roll size can be customized | ||

| Length | m | 200 | 200 | 200 | 420 | 280 | 210 | 168 | 140 | 105 | 84 | 70 | |||

| Roll Area | m2 | 1400 | 1400 | 1400 | 2940 | 1960 | 1470 | 1176 | 980 | 735 | 588 | 490 | |||

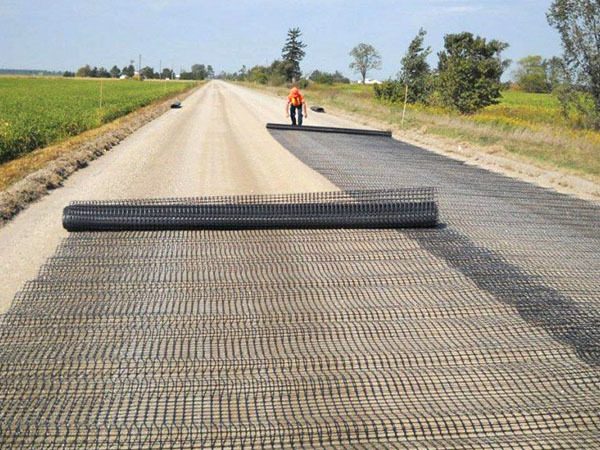

Application

1. Water management initiatives: HDPE geomembrane is ideal for creating anti-seepage and isolation layers in channels, reservoirs, and anti-seepage walls within water management initiatives.

2. Soil contamination mitigation: HDPE geomembrane serves as an isolation layer at the base and sides of soil contamination mitigation projects, effectively preventing the infiltration and spread of pollutants.

3. Infrastructure Projects: HDPE geomembrane can function as a waterproof isolation layer in basements, underground facilities, and other infrastructure projects.

4. Artificial lakes and aquaculture: HDPE geomembrane is utilized as an impermeable layer in artificial lakes, pools, and aquaculture settings to ensure that water remains contained without leakage.

5. Waste disposal sites: HDPE geomembranes are employed as anti-seepage layers in landfills to avert waste leakage and protect groundwater from contamination.

Features

1. Chemical corrosion resistance: The HDPE geomembrane exhibits remarkable resistance to chemical corrosion from substances such as acids, alkalis, and salts, making it suitable for a variety of soil conditions.

2. Exceptional strength: This geomembrane demonstrates outstanding tensile strength and tear resistance, enabling it to endure significant loads and extrusion forces in various applications.

3. Enhanced durability: The HDPE geomembrane is designed to withstand weathering, effectively resisting ultraviolet radiation and the impacts of climate change, thereby ensuring consistent material performance.

4. Low water permeability: The HDPE geomembrane is essentially impermeable, providing effective barriers against penetration and isolation, making it ideal for projects that necessitate such protective measures.

5. Environmentally friendly: Constructed from eco-friendly materials, the HDPE geomembrane is non-toxic, odorless, and recyclable, ensuring it does not contribute to environmental pollution.

In an era where environmental protection and infrastructure durability are paramount, finding a reliable, high-performance barrier material is crucial. Did you know that a single millimeter of this material can effectively block harmful contaminants for decades? This is where HDPE Geomembrane comes into play, establishing itself as the premier choice for critical containment projects worldwide.

Unmatched Product Features & Advantages

The exceptional performance of HDPE Geomembrane stems from its core characteristics. It boasts excellent anti-penetration performance, creating an impermeable barrier that effectively prevents seepage and isolates contaminants. Its remarkable chemical corrosion resistance allows it to withstand exposure to a wide range of acids, alkalis, and salts, making it ideal for harsh environments like landfills and industrial sites. Furthermore, this geomembrane possesses outstanding tensile strength, tear resistance, and puncture resistance, enabling it to bear significant loads and ground movements without compromising its integrity. Designed for long-term durability, it resists UV radiation and extreme weather conditions, ensuring project longevity. As an environmentally friendly material, it is non-toxic and recyclable, aligning with sustainable development goals.

Advanced Material & Manufacturing Process

Our HDPE Geomembrane is engineered using premium raw materials and advanced production techniques, such as the three-layer blow molding or calendering processes. This results in a consistent, high-density polyethylene sheet with superior mechanical properties. Key technical indicators, including density, stress crack resistance (≥500 hrs per ASTM D5397), and oxidative induction time, are rigorously tested to meet international standards like ASTM and GRI. The product is available in various thicknesses (0.2mm to 3.0mm), widths (up to 10m), and colors (black, white, green), all customizable to fit specific project requirements.

Versatile Applications

The versatility of the HDPE Geomembrane is demonstrated across numerous sectors:

Water Management: Securing reservoirs, canals, and irrigation systems against water loss.

Environmental Protection: Lining landfills and soil remediation sites to prevent pollutant migration.

Mining & Energy: Containing leachate in tailings ponds and secondary containment.

Aquaculture & Agriculture: Lining ponds and canals to ensure efficient water usage.

Civil Infrastructure: Waterproofing for tunnels, basements, and underground structures.

In conclusion, whether your project demands ultimate chemical resistance, superior mechanical strength, or long-term environmental sustainability, the HDPE Geomembrane delivers proven performance and reliability. It is more than just a material; it's a long-term investment in the safety and success of your project.

Packaging and shipping

We are willing to package and ship products according to the weight, specifications, materials, economic costs and customer requirements.

Customer review

Customer visits

Exhibition

Certification

Our products are applied in these fields

Non woven geotextile

Geonet

LLDPE Geomembrane

HDPE Geomembrane

Uniaxial Geogridac

Triaxial Geogrid

Steel-Plastic Geogrid

PP Biaxial Geogrid

PET Geogrid

Fiberglass Geogrid

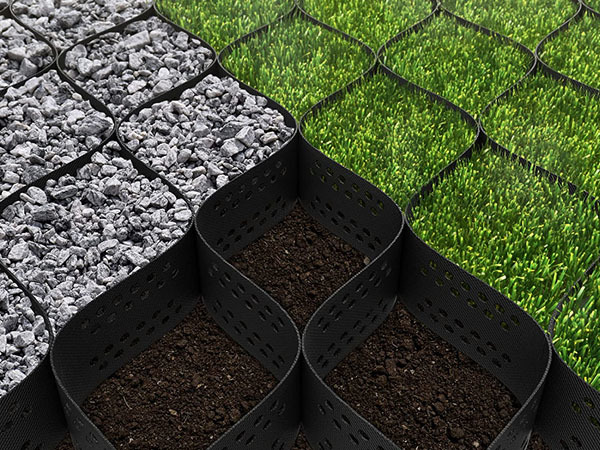

Geocell

Non woven geobag

Frequently Asked Questions

— What is your method of payment?

We accept T/T, L/C, Western Union or negotiation. Don't worry about anything, if you have any questions please feel free to contact us.

— How long is your delivery time?

Small orders take about one week, large orders need to be negotiated based on factory orders.

— How do you guarantee the quality of the product for us?

We have a professional quality control team, and each product is strictly inspected before shipment.

— Can you have our brand printed on your products?

Yes. If you can meet our MOQ, we can print your logo on the product and packaging.

— Can we get the sample from your factory?

We can provide you with samples for free, but you need to pay the express fee before the first cooperation.

— Do you accept processing orders?

We provide OEM and ODM services to customers.

GET A FREE QUOTE

RELATED PRODUCTS